Recognizing the Performance of Membrane Layer Switches for Customer User Interface Tools

The capability of membrane switches over stands for a significant advancement in customer interface design, incorporating efficiency with aesthetic versatility. As markets significantly focus on individual experience, comprehending the nuances of membrane button technology becomes important.

What Are Membrane Switches?

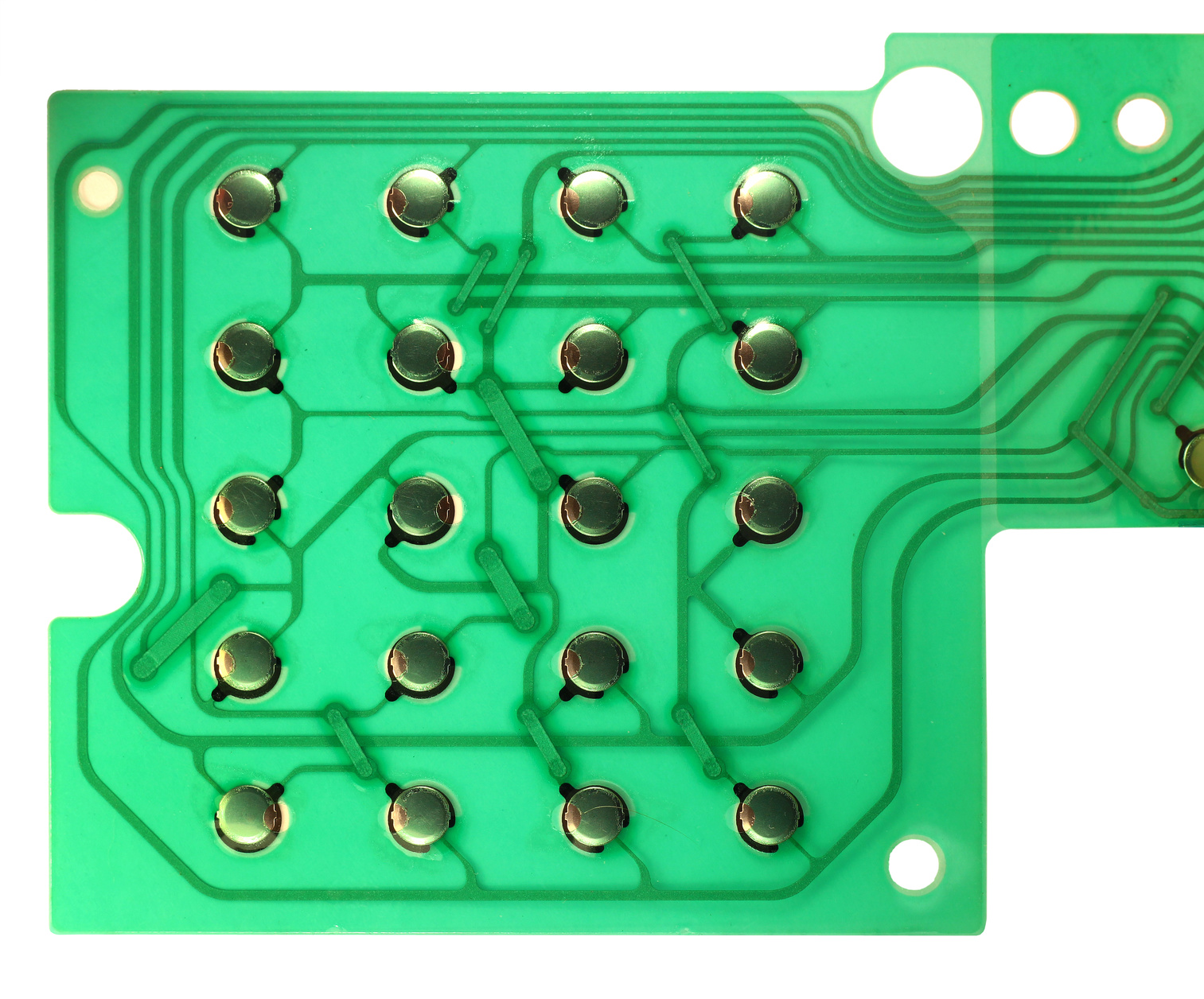

Membrane layer switches are cutting-edge user interface tools that promote individual interaction with digital devices. These flexible parts contain several layers, consisting of a graphic overlay, spacer, and a published circuit layer. The style enables a smooth assimilation right into different digital devices, enhancing both the aesthetic and functional facets of customer interfaces.

Membrane layer buttons are frequently utilized in a variety of applications, from house appliances to industrial equipment and clinical devices. Their construction typically features a slim profile, making them a perfect option for portable layouts. The responsive feedback offered by these switches can be crafted to meet particular user preferences, making certain reliable communication in between the individual and the gadget.

Sturdiness is another considerable advantage of membrane layer buttons, as they are immune to dirt, wetness, and chemicals, which enhances their lifespan in requiring environments. Furthermore, these buttons can be personalized in terms of form, dimension, and visuals style, allowing for branding and user-specific functions. Generally, membrane switches over stand for a functional option for boosting individual experience in digital gadgets, incorporating functionality with visual appeal in a reliable fashion.

Just How Membrane Switches Over Job

Operating on an uncomplicated principle, membrane switches make use of a layered building to register user input efficiently. Each switch contains several layers, including a printed circuit layer, a spacer layer, and a leading graphic layer, which are created to interact effortlessly. When a customer presses the leading layer, it presses the spacer layer, bringing the conductive components of the circuit layer right into call with each other.

This contact creates a closed circuit, signaling the tool to execute a specific feature. The style permits different arrangements, including tactile comments, which can improve the customer experience by providing a physical sensation upon activation. The materials used in membrane switches often include flexible substratums, such as polyester or polycarbonate, which make sure toughness and strength against wear and tear.

Key Advantages of Membrane Buttons

An additional significant benefit is their compactness. Membrane layer buttons are slim and light-weight, which makes it possible for producers to conserve space in their tools without compromising performance. This attribute is specifically advantageous in applications where weight and quantity are crucial considerations.

Furthermore, membrane layer switches are immune to dirt, wetness, and chemicals, boosting their toughness. This durability expands their lifespan and decreases the requirement for regular substitutes, resulting in expense financial savings gradually.

Furthermore, the tactile feedback offered by membrane layer buttons can be optimized to enhance individual communication. They can include features such as elevated switches or distinct clicks, boosting use and customer experience.

Applications Throughout Industries

Individual user interface tools using membrane layer switches are common in a large range of sectors, showcasing their adaptability and capability. Membrane Switch. In the clinical industry, membrane layer switches are important to tools such as analysis devices and individual surveillance systems, where their durability and simplicity of cleaning are important for preserving health standards. In the automotive sector, these buttons are employed in dashboard controls and infomercial systems, offering a sleek and modern-day user interface for individuals.

Moreover, the customer electronic devices industry take advantage of membrane layer buttons in home appliances and handheld gadgets, where compact layout and easy to use user interfaces boost user experience. Industrial applications likewise leverage membrane changes for control board in machinery and automation systems, highlighting their effectiveness and resistance to rough settings.

In the aerospace and protection markets, membrane layer switches are utilized in cabin controls and devices, where reliability and performance under extreme conditions are critical. Additionally, the video gaming sector significantly integrates membrane layer buttons in controllers and game equipments, contributing to an appealing user experience. In general, the versatility of membrane layer switches enables their widespread usage throughout various fields, that site emphasizing their relevance in contemporary interface style.

Future Trends in Membrane Switch Modern Technology

Additionally, the use of sophisticated products, such as polycarbonate and polyester movies, is expected to climb, giving improved sturdiness and resistance to environmental stress factors. These products add to the general longevity of membrane switches, making them appropriate for harsher industrial applications.

Furthermore, the consolidation of wise modern technology, including IoT connectivity, will allow membrane switches to communicate with other tools and systems, assisting in a much more interactive individual experience. This fad lines up with the expanding need for smart gadgets across various sectors, from health care to consumer electronic devices.

Last but not least, modification choices are prepared for to expand, permitting producers to create bespoke solutions tailored to specific individual demands and choices. These developments will certainly place membrane layer switches as necessary elements in the development of user interface technology.

Conclusion

In conclusion, membrane layer changes stand for a pivotal advancement in user interface innovation, using a trusted and versatile service for varied digital applications. site web As developments in product scientific research and touch noticing innovations proceed, the performance and applicability of membrane switches are anticipated to increase, enhancing their value in modern electronic tools.